Hyundai Advanced Materials

provides optimal solutions based on the latest technology by supporting injection molding and structural analysis throughout the customers’ product development process. This enables precise analysis and maximizes product quality and mass production.

- CAE software overview

-

Injection molding analysis

- #flow

- #cooling

- #deformation

- #gate optimization

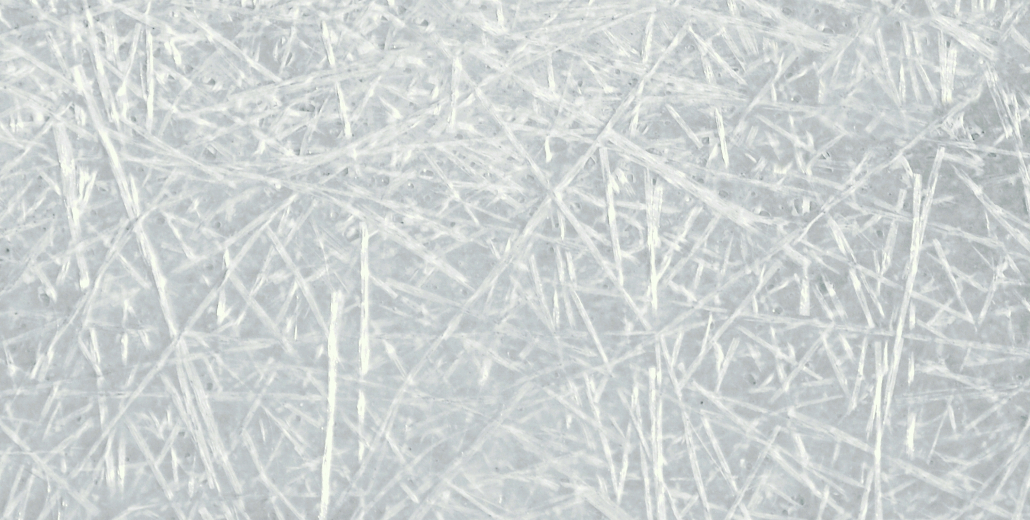

GF orientation application

- #rigidity

- #pressure resistance

- #vibration

- #thermal deformation

Structural analysis

- #rigidity

- #vibration

- #thermal deformation

- #impact

- #dynamic analysis

- #vibration sound

Fluid analysis

- #fluid flow

- #hydraulics

- #velocity

- Injection molding analysis

-

We predict potential issues during the injection molding process in advance and provide optimal solutions to resolve them. This ensures product quality by improving the causes of molding defects through injection molding analysis, while supporting cost reduction and process optimization.

- Analyzing filling flow patterns

- Verifying molding deformation and shrinkage

- Optimizing gate systems and molding conditions

- Predicting molding defects and proposing improvement of design

- Structural analysis

-

We analyze how products perform in real-use environments and provide improvements to secure optimal strength and durability. This strengthens product safety and performance and enables efficient enhancements from the early design stages.

- Verifying the strength and thermal deformation effects on molded parts

- Identifying vulnerable areas under vibration and excitation conditions

- Predicting damage under impact and dynamic operating conditions

- Proposing design and material optimizations

- Injection-structure coupled analysis

-

We conduct structural analysis reflecting injection molding results to provide reliable outcomes that closely simulate actual molded products. This allows comprehensive evaluation of strength reductions at weld line locations and mechanical property variations due to glass fiber orientation, enabling targeted improvement recommendations.

- Considering the impact of strength reduction at weld line locations

- Reviewing the effect of property variations due to differences in GF orientation